This website uses cookies to ensure you get the best experience. Please see our Privacy Policy for more information.

Vacuum Heaters

At Thermic Edge, we pride ourselves on being at the forefront of the vacuum furnace industry. Providing a complete service, our bespoke versatile ranges gives you the tools necessary for any application.

On this page, you will find information on our standard heating solutions that we offer in addition to our Versatile and Button heater ranges. These include:

Any of these heaters can be integrated with our stages to provide:

Click to Download our product brochure for the Thermic Edge 1000°C Carbon-Carbon Composite Element Heater (Head only).

Click to Download our product brochure for the Thermic Edge 1000°C Carbon-Carbon Composite Element Heater (Flange mount).

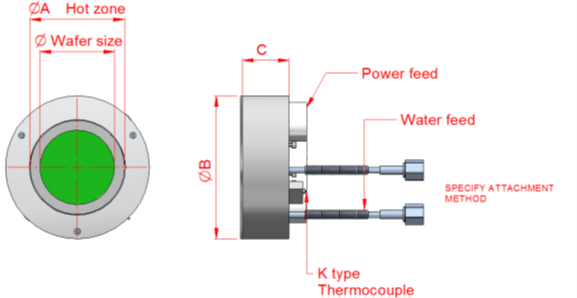

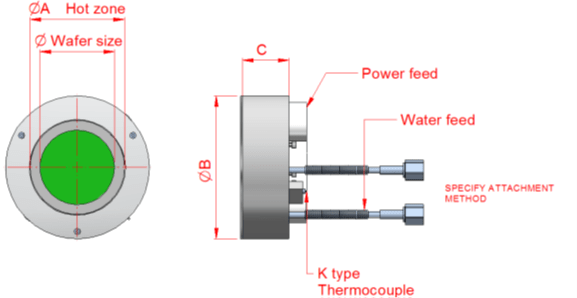

| Part No | ØA – Hot Zone | ØB – Heater o.d. | C – Heater Thickness | Mounting | *Voltage Max | *Current Max | *Power Max |

| HTWM6-SiC-01 | 26mm (1”) | 36.6mm | 52mm | M6 stud | 6v | 39a | 234w |

| HTWM6-SiC-01.5 | 38.1mm (1.5”) | 48.7mm | 52mm | M6 stud | 10v | 39a | 390w |

| HTWM6-SiC-02 | 50.8mm (2”) | 61.4mm | 52mm | M6 stud | 15v | 39a | 585w |

| Part No | ØA – Hot Zone | ØB – Heater o.d. | C – Heater Thickness | Mounting | *Voltage Max | *Current Max | *Power Max |

| HTWM6-CCC-01 | 26mm (1”) | 36.6mm | 52mm | M6 stud | 6v | 39a | 234w |

| HTWM6-CCC-01.5 | 38.1mm (1.5”) | 48.7mm | 52mm | M6 stud | 10v | 39a | 390w |

| HTWM6-CCC-02 | 50.8mm (2”) | 61.4mm | 52mm | M6 stud | 15v | 39a | 585w |

*In Vacuum @ 1000°C (Element Temp.)

Our high temperature oxygen resistant heaters using solid Silicon Carbide (SiC) or SiC coated graphite elements

Click to Download our product brochure for the Thermic Edge 1000°C Carbon-Carbon Composite Element Heater (Head only).

Click to Download our product brochure for the Thermic Edge 1000°C Carbon-Carbon Composite Element Heater (Flange mount).

| Part No | Ø Wafer size | ØA – Hot Zone | ØB – Heater o.d. | C – Heater Thickness | *Voltage Max | *Current Max | *Power Max |

| HTSW-CCC-03 | 77mm (3”) | 90 | 149 | 42 | 60 | 25 | 1500 |

| HTSW-CCC-04 | 102mm (4”) | 116 | 175 | 42 | 60 | 40 | 2400 |

| HTSW-CCC-05 | 128mm (5”) | 141 | 200 | 42 | 60 | 60 | 3600 |

| HTSW-CCC-06 | 153mm (6”) | 166 | 225 | 42 | 60 | 80 | 4800 |

| HTSW-CCC-07 | 179mm (7”) | 192 | 251 | 42 | 60 | 110 | 6600 |

| HTSW-CCC-08 | 204mm (8”) | 218 | 277 | 42 | 60 | 140 | 8400 |

*In Vacuum @ 1200°C

Our highest standard heaters will operate with a top plate temperature at 1700°C. The heater size can be increased as required.

Click to Download our product brochure for the Thermic Edge 1000°C Carbon-Carbon Composite Element Heater (Head only).

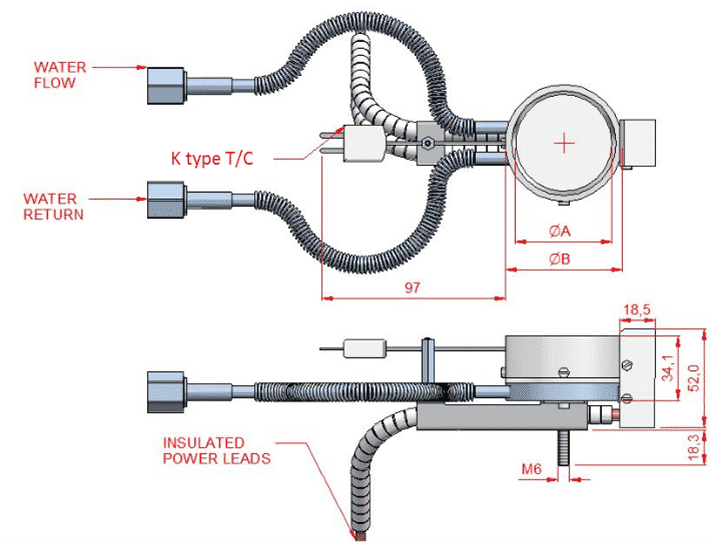

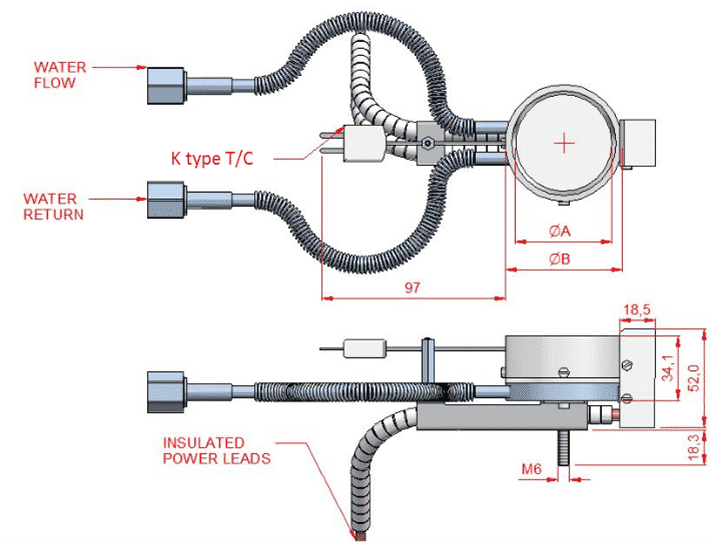

| Part No | ØA – Hot Zone | ØB – Heater o.d. | C – Heater Thickness | Mounting | Voltage Max | Current Max | Power Max |

| HTWM6-CCC-01 | 26mm (1”) | 36.6mm | 52mm | M6 stud | 17 volts | 33 amps | 561 Watts |

| HTWM6-CCC-01.5 | 38.1mm (1.5”) | 48.7mm | 52mm | M6 stud | 40 volts | 30 amps | 1200 Watts |

| HTWM6-CCC-02 | 50.8mm (2”) | 61.4mm | 52mm | M6 stud | 60 volts | 35 amps | 2100 Watts |

*In Vacuum @ 1900°C (Element Temp.)

| Part No | Ø Wafer size | ØA – Hot Zone | ØB – Heater o.d. | C – Heater Thickness | Voltage Max | Current Max | Power Max |

| HTSW-CCC-03 | 77mm (3”) | 90 | 149 | 42 | 60 | 25 | 1500 |

| HTSW-CCC-04 | 102mm (4”) | 116 | 175 | 42 | 60 | 40 | 2400 |

| HTSW-CCC-05 | 128mm (5”) | 141 | 200 | 42 | 60 | 60 | 3600 |

| HTSW-CCC-06 | 153mm (6”) | 166 | 225 | 42 | 60 | 80 | 4800 |

| HTSW-CCC-07 | 179mm (7”) | 192 | 251 | 42 | 60 | 110 | 6600 |

| HTSW-CCC-08 | 204mm (8”) | 218 | 277 | 42 | 60 | 140 | 8400 |

*In Vacuum @ 1200°C

Advanced carbon-carbon composite element and high thermal conductivity technical ceramics and graphite grades allow top plate temperatures of up to 1900°C with a very fast ramp rate.

All heaters are supplied with power leads and internal thermocouples and can be supplied with power supplies and controllers.

At Thermic Edge, we pride ourselves on being at the forefront of the Vacuum Heating Technology Industry. We provide a complete service, our bespoke and versatile ranges give you the tools necessary for any inert, HV or UHV application.

This website uses cookies to ensure you get the best experience. Please see our Privacy Policy for more information.