This website uses cookies to ensure you get the best experience. Please see our Privacy Policy for more information.

Vacuum Heaters

At Thermic Edge, we pride ourselves on being at the forefront of the vacuum furnace industry. Providing a complete service, our bespoke versatile ranges gives you the tools necessary for any application.

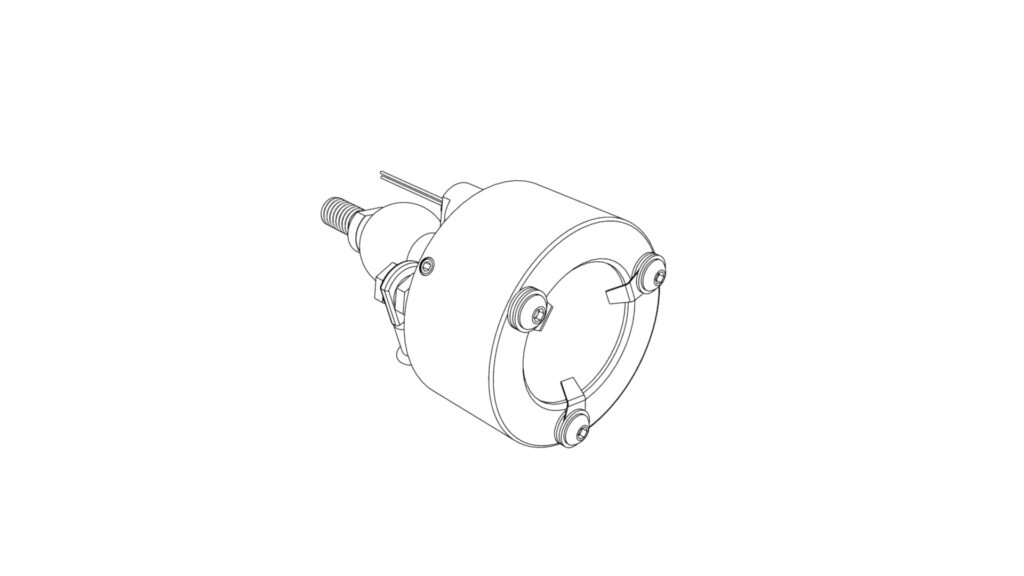

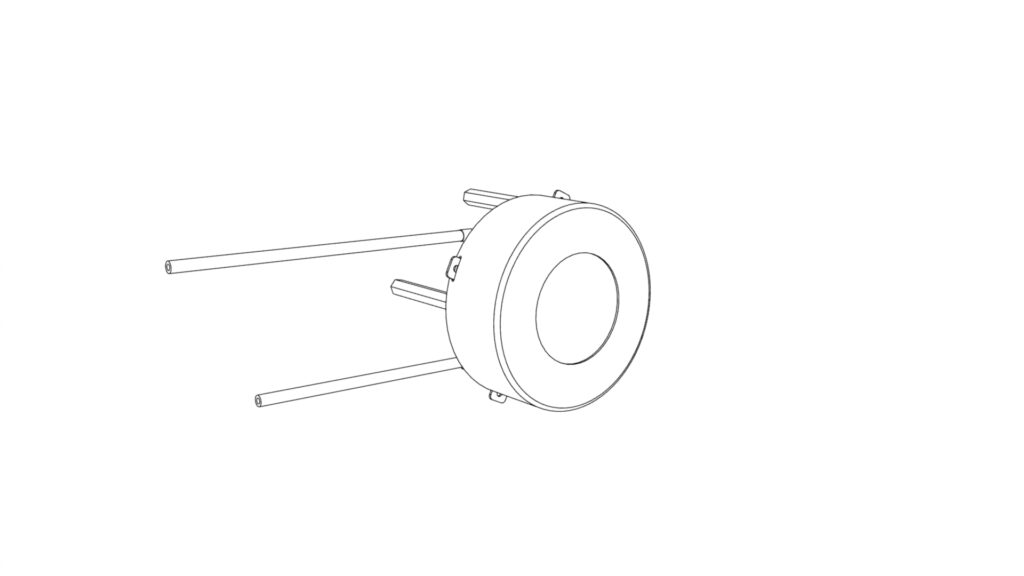

At Thermic Edge, we supply cost-effective, high uniformity Wafer Heaters, Vacuum Heaters and Sample Heaters to research and industry for thin film deposition and sample processing. Our Sample heaters can be supplied with retainers or clips to hold a range of semiconductor wafers or samples.

All heaters go through comprehensive testing. Our in-house testing capabilities include helium leak checking, full temperature testing using vacuum test system and uniformity testing using a FLIR thermal imaging camera. Thermic Edge is ISO 9001 Certified.

The Thermic Edge design team work closely with clients to provide:

All heaters go through comprehensive testing. Our in-house testing capabilities include helium leak checking, full temperature testing using vacuum test system and uniformity testing using a FLIR thermal imaging camera. Thermic Edge are ISO 9001:2015 registered.

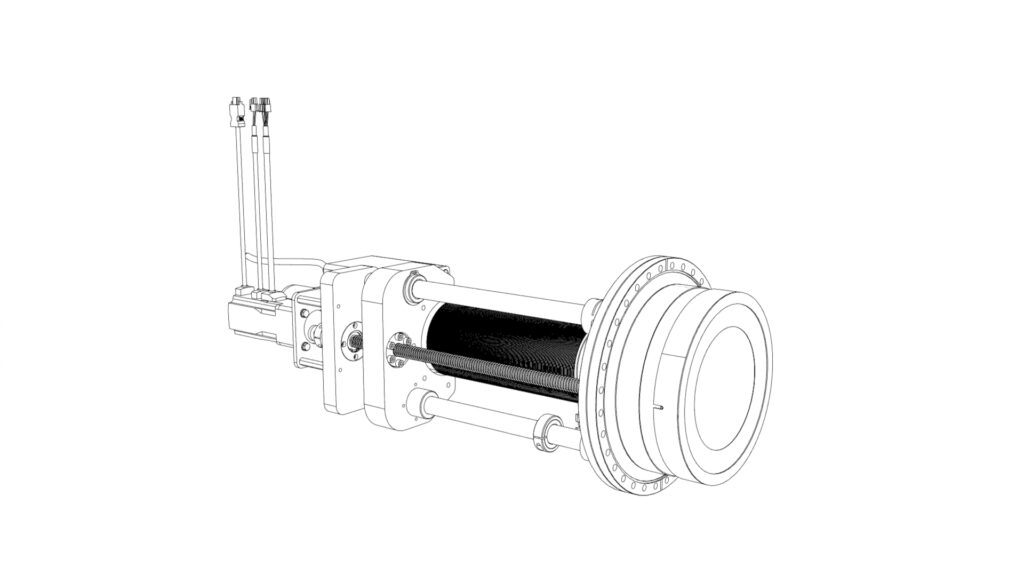

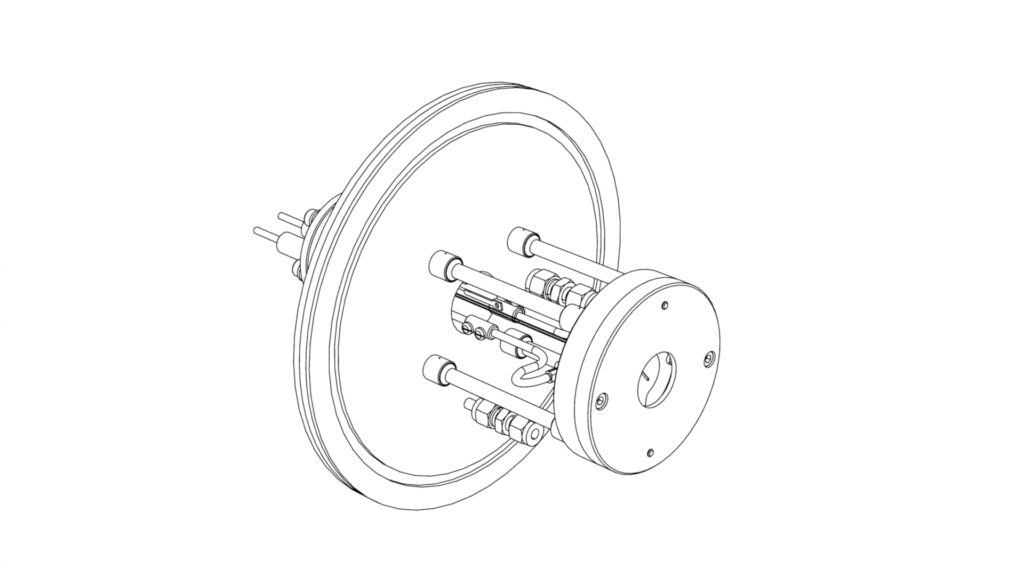

Thermic Edge offers a complete range of sample heating hot stages for all thin film deposition system applications. Heaters and samples can be mounted in any orientation and the Thermic Edge range of manipulators provides cost effective options for sample rotation, heater rotation, sample transfer and sample/heater positioning.

Sample heating stages can be offered with sample biasing (RF or DC) up to 1000W and complete with temperature controller and power supply. For heaters and stages with RF biasing, full shielding and power/thermocouple line filtering can be supplied. Water cooled heaters can be supplied with chillers.

Thermic Edge specialises in providing bespoke solutions for heating applications that cannot be fulfilled using standard heaters and stages. The Thermic Edge design team works closely with clients to provide:

Manual detailing installation, specification, and operation instructions

Contact our technical sales team today if you need any assistance or a larger heater size.

Additional Options include, but are not limited to:

Click to Download our product brochure for all Thermic Edge Element materials.

At Thermic Edge, we pride ourselves on being at the forefront of the Vacuum Heating Technology Industry. We provide a complete service, our bespoke and versatile ranges give you the tools necessary for any inert, HV or UHV application.

This website uses cookies to ensure you get the best experience. Please see our Privacy Policy for more information.